W J Webb & Co Ltd offer specialised rubber mouldings to clients throughout the UK, Europe and the USA. Our clients include several large organisations in aerospace, military, veterinary, agricultural, marine and automotive (including vintage) industries.

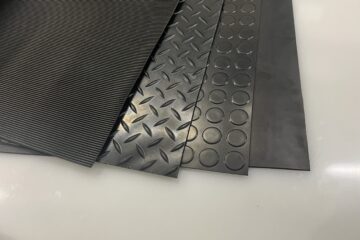

We have been producing rubber mouldings to our clients exact specifications for over 60 years and are able to manufacture components in a wide range of compounds. We also manufacture and supply rubber matting and accessories such as valve grinding tools and brake bleed tubes to the automotive industry.

We are based in the quiet rural village of Whaplode Drove near Spalding, Lincolnshire. We started out in 1960 and have many years of experience in the rubber manufacturing sector. With our excellent knowledge we can assist with the design and manufacture of rubber mouldings to our clients specific requirements. All enquires are dealt with promptly and we can offer free competitive quotes for the manufacture of tooling and production of your rubber mouldings.

UKAS accredited since 2021

ISOQAR Cert No. 20517

Certified ISO9001:2015

ISO Compliant since 1997

We can help you every step of the way whether you have CAD drawings, a sketch or even just an idea.

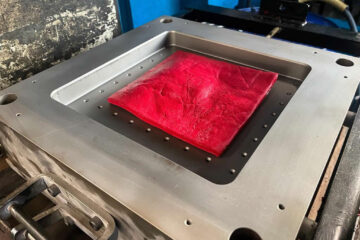

We work closely with our toolmakers to produce you the best, most efficient and accurate moulds to your specified tolerances.

Our toolmakers use CNC machining, milling, turning, and spark erosion along with other processes to get the job done.

Making single or multi cavity tools from tooling-grade aluminum or P20 grade steel for production tooling.

Get in touch for a free quote now

Contact us here

Our free quoting process is simple and efficient. Call or email us to discuss your requirements, send us a sketch or a drawing along with any specific requirements and we will do the rest!

We can provide drawing and design work, quotes for sample tooling in aluminum or full production tooling in steel. Let our team help you choose the most cost-effective material that meets the specific needs of your product. Price breaks available on larger quantities or cost per part for bespoke orders.

UK based, European or world wide, shipped direct to your door.

So no matter how big or small your project, contact us for a free, friendly and professional service today!