New and reconditioned metal parts need cleaning before being moulded. These are usually shot blasted to etch or clean away any rust or debris from the surfaces. Each part is then carefully cleaned and inspected to make sure all debris is removed.

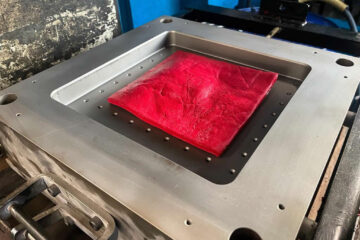

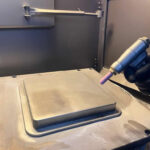

During a long run and after use, the mould itself can need cleaning. Residue from release agents and build up from the compound itself needs removing as it can also leave unsightly marks on the mouldings. Before storing the mould, a moisture guard should be applied to prevent any rust or seizing. This is cleaned off the mould before it’s used again.